5 Reasons Why Industry Leaders Prefer Trusted Compact X Ray Source Equipment Suppliers

Precision, reliability, and efficiency are critical factors in industrial inspection, quality control, and research applications. Across sectors such as electronics, aerospace, automotive, and medical devices, accurate X-ray imaging ensures defect detection, process optimization, and safety compliance. Choosing the right compact X-ray source equipment suppliers is not merely a transactional decision but a strategic investment in operational excellence. Trusted suppliers provide advanced systems, expert guidance, and seamless integration capabilities that help organizations maintain high standards, reduce operational risks, and achieve long-term growth.

This blog explores five reasons why leading companies consistently partner with reliable suppliers for compact X-ray systems, offering insights into performance, efficiency, and industry best practices.

1. Proven Industry Expertise and Track Record

- Demonstrated Reliability: Suppliers with extensive industry experience consistently deliver high-quality X-ray systems that meet even the most complex inspection requirements. Their proven expertise reduces the likelihood of equipment malfunctions and minimizes operational downtime. Partnering with reliable suppliers ensures sustained performance and confidence in critical inspection processes.

- Successful Client Portfolio: A robust track record across diverse industries demonstrates a supplier’s ability to handle a wide range of applications, from microelectronics inspection to aerospace component analysis. Working with such suppliers assures adaptability and technical competence. This breadth of experience reinforces confidence in their solutions and service quality.

- Consultative Approach: Experienced suppliers offer pre-sales guidance, helping organizations select systems tailored to specific inspection workflows and operational objectives. They evaluate client needs, recommend optimal configurations, and ensure seamless integration into existing processes. This consultative support improves efficiency, reduces errors, and maximizes return on investment.

Partnering with experts ensures that organizations have access to systems that perform reliably under demanding conditions, providing a foundation for scalable, high-precision operations.

2. Advanced Technology and Customization Options

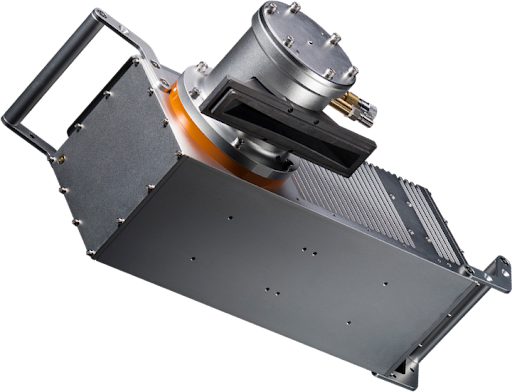

- Cutting-Edge Imaging Systems: Industry leaders choose suppliers that provide high-resolution imaging systems, microfocus X-ray sources, and advanced automation features for precise inspections. This technology enables the accurate detection of even the smallest defects, ensuring product quality and reliability. By leveraging cutting-edge systems, companies can maintain competitive standards across critical industrial applications.

- Customizable Configurations: Trusted suppliers offer systems that allow precise adjustments of voltage, focal spot, and beam alignment to suit specific production and inspection requirements. Customization ensures that the equipment can handle unique applications effectively. Tailored configurations optimize imaging accuracy, reduce errors, and enhance overall operational efficiency.

- Seamless Integration: Modern X-ray systems are designed to integrate smoothly with existing workflows, software platforms, and automated production lines. Seamless compatibility reduces operational friction, minimizes downtime, and accelerates inspection processes. Efficient integration ensures that companies can maintain high throughput without compromising accuracy or reliability.

Access to innovative and adaptable systems enables companies to optimize inspection processes, improve throughput, and maintain quality control across diverse product lines.

3. Comprehensive Support and Service

- Installation and Commissioning: Leading suppliers provide comprehensive installation and setup support, ensuring that X-ray systems operate at peak efficiency from day one. Proper commissioning minimizes operational errors, accelerates workflow integration, and guarantees optimal system performance. This foundation allows organizations to begin inspections confidently and without delays.

- Predictive Maintenance and Training: Regular maintenance schedules, remote diagnostics, and operator training programs help extend equipment lifespan while reducing unplanned interruptions. Predictive maintenance identifies potential issues before they affect operations, ensuring consistent performance. Well-trained personnel can operate systems safely and efficiently, maximizing productivity and ROI.

- Responsive After-Sales Service: Trusted suppliers offer prompt technical assistance, troubleshooting, and ready access to spare parts, ensuring uninterrupted operation. Responsive support minimizes downtime and protects operational continuity. Reliable after-sales service builds long-term partnerships, giving organizations confidence in both equipment performance and supplier expertise.

Comprehensive support not only maintains operational efficiency but also gives organizations confidence in the long-term reliability and performance of X-ray systems.

4. Compliance and Safety Assurance

- Adherence to International Standards: Suppliers that comply with ISO certifications, radiation safety standards, and industry regulations provide systems that meet rigorous operational and legal requirements. This ensures reliability while maintaining adherence to local and international compliance norms. Following recognized standards enhances organizational credibility and minimizes regulatory risks.

- Built-In Safety Protocols: Advanced compact X-ray systems incorporate safety measures such as thermal management, overload protection, and emergency shutdown mechanisms. These protocols protect both operators and equipment from potential hazards during high-voltage operation. Prioritizing safety reduces downtime, prevents accidents, and supports continuous, efficient performance.

- Operational Reliability: Strict compliance with standards and safety regulations ensures systems consistently deliver accurate, high-quality imaging results. Reliable operation minimizes risks of performance degradation or unexpected failures. Consistent reliability allows organizations to maintain quality control, meet production schedules, and achieve long-term operational efficiency.

Safety-conscious suppliers reduce legal and operational risks while maintaining efficiency, allowing organizations to focus on quality control and innovation.

5. Cost-Efficiency and Operational Optimization

- Reduced Product Waste: Early detection of defects prevents faulty products from moving further along the production line, minimizing material waste and costly rework. This proactive approach ensures that only high-quality components reach the final stages. Over time, it improves efficiency, reduces operational expenses, and safeguards brand reputation.

- Energy Efficiency: Advanced integrated X-ray source manufacturers design systems to optimize energy consumption while delivering consistent, high-performance output. Reduced energy usage lowers operational costs and supports sustainability goals. Efficient power management also extends equipment life and ensures reliable performance during intensive inspection cycles.

- Long-Term Investment Value: Durable components and predictive diagnostics reduce unplanned maintenance and extend system lifespan. Minimal upkeep requirements lower operational burdens and costs over time. This ensures a high return on investment, allowing businesses to maximize value while maintaining precise and dependable X-ray inspection capabilities.

Partnering with trusted suppliers ensures that businesses achieve financial efficiency while maintaining high-quality inspection standards, protecting both the bottom line and brand reputation.

Final Thoughts:

Collaborating with trusted high-voltage power supply manufacturers ensures stable, efficient, and safe operation across a wide range of industrial applications. These collaborations provide consistent energy delivery, safeguard critical equipment, and maintain optimal system performance under demanding conditions.

Organizations seeking reliable, high-performance X-ray solutions that deliver precision, innovation, and durability can partner confidently with VJ X-Ray. By leveraging their extensive expertise, cutting-edge equipment, and customized, industry-specific support, businesses gain a strategic advantage in quality control, operational efficiency, and long-term reliability, ensuring consistent performance and measurable results across diverse applications.